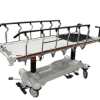

Hill-Rom Stretchers

Hill-Rom Stretchers are innovative, working to provide you with the right products that deliver the highest quality care. Our 10-Step Reconditioning Process ensures you get the same quality and performance. Piedmont Medical, Inc. is the leader in reconditioned Hill-Rom Beds and Stretchers.

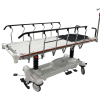

Stryker Stretchers

Rising to the demand of healthcare professionals, Stryker Stretchers are designed to assist caregivers, ensure safety, maximize efficiency and enhance the patient experience. Piedmont Medical, Inc. takes great pride in continuing that same spirit by reconditioning our products to the standards they hold so high.

Reconditioned Medical Stretchers

Piedmont Medical has been reconditioning used hospital beds and stretchers for over 26 years. We apply our expertise and innovative techniques to every piece of furniture we offer, which ensures the unsurpassed quality of our reconditioned medical stretchers.

A quality stretcher is indispensable for patient transportation and care, which is why our refurbished Stryker stretchers have flawless functionality. We work to provide every patient and medical care team with reliable equipment that promotes comfort, safety, and efficiency.

Browse our inventory of refurbished stretchers to find equipment with the features you require, such as adjustable foot and head sections. Every stretcher in our inventory supports patient stability in transit. For instance, smooth-rolling wheels with locking mechanisms make navigating narrow hallways and busy hospital corridors easier.

Provide the best patient care possible with our cost-effective reconditioned medical stretchers. Shop today for durable and high-performing equipment.

Reconditioning

State of the Art Reconditioning Process

- The stretcher is visually inspected for bent or broken parts. Any bent or broken parts are repaired or replaced so that operating features function properly.

- The stretcher frame is completely disassembled.

- The stretcher frame is cleaned. All stickers and/or decals are removed, if necessary.

- The stretcher frame, arm rails and pans (if applicable) is sanded completely in a separate room.

- The stretcher frame and parts are then cleaned again to remove any dust or dirt.

- The stretcher frame, arm rails, and pans are painted in a professional paint booth. If necessary, they are baked dry. They are left to dry for 24 hours before they are touched again.

- The stretcher frame is then reassembled to include the following NEW parts, IF NECESSARY: *OEM casters and assembly for new brake and steer *Plastic wheel covers and arm rail plastics *Head and Foot Boards with your choice of inserts in each *Labels and/or decals *Capacitors and motor grease is replaced *Couplers

- A final inspection of the stretcher operating features is rechecked and electrical safety tested to ensure the stretcher is performing to manufacturers standards.

- The stretcher is shipped and wrapped in protective plastic.

It is then blanket wrapped and can be positioned in custom stands for stability.